Heat pumps have become a cornerstone of energy-efficient heating and cooling for both homes and businesses, especially in regions committed to sustainable energy solutions. Their ability to provide warmth in winter and cooling in summer with minimal energy use makes them an attractive choice. However, like any mechanical system, they can develop problems that require heat pump repair. Knowing how to identify and troubleshoot these issues can save money, prevent downtime, and extend your system’s life.

Heat pumps are central to achieving net-zero building emissions. Proper installation and upkeep are not just about comfort, they directly impact sustainability goals.

Understanding Heat Pump Repair and How Heat Pumps Work

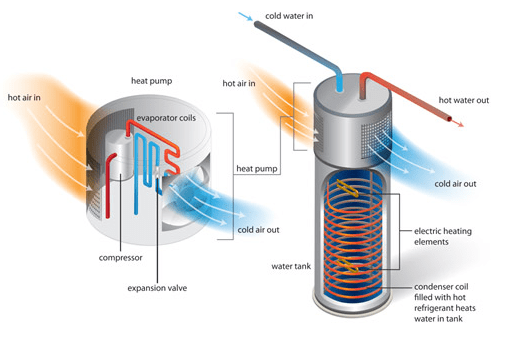

Heat pumps operate by transferring heat between indoor and outdoor environments using refrigerant, coils, and a compressor. In heating mode, they extract heat from outside air (even in cold conditions) and move it indoors. In cooling mode, the process reverses. This efficiency is why modern heat pumps can reduce electricity consumption for heating by up to 50% compared to electric resistance heating.

To achieve this, the system relies on precise refrigerant flow and well-maintained components. Even minor issues, such as a dirty coil or low refrigerant, can disrupt the delicate balance required for optimal performance. For example, in cold climates, advanced models use variable-speed compressors to maintain efficiency without excessive strain. Understanding the basic operation, heat absorption, compression, and release, helps homeowners and businesses identify when something is amiss. The more familiar you are with how your unit works, the easier it is to spot early warning signs and take corrective action before efficiency drops or damage occurs.

When problems occur, performance and efficiency drop, and energy bills can spike. According to HVAC service data from 2024, over 60% of heat pump repair calls are related to airflow restrictions, often due to dirty filters or blocked coils.

| Common Issue | Impact | Frequency |

|---|---|---|

| Dirty Filters | Reduced airflow and efficiency | High |

| Refrigerant Leaks | Loss of heating/cooling | Medium |

| Electrical Failures | System shutdown | Medium |

Common Heat Pump Repair Issues and Their Causes

Dirty Filters and Clogged Coils in Heat Pump Repair

One of the most frequent problems is restricted airflow caused by dirty filters or clogged coils. This forces the system to work harder, reducing efficiency and potentially leading to component failure. Over time, excessive strain can shorten the lifespan of the compressor and fan motor. In dusty environments or homes with pets, filters can clog faster, making monthly inspections essential.

Incorrect Thermostat Settings During Heat Pump Repair

Sometimes, the issue is as simple as having the thermostat set incorrectly, such as being in cooling mode when heating is needed. Seasonal changes often catch users off guard, and a quick check of settings can resolve many complaints. Advanced programmable thermostats can help avoid these mistakes by automatically adjusting based on pre-set schedules.

Refrigerant Leaks in Heat Pump Repair Cases

Low refrigerant levels can severely reduce performance and damage the compressor. In addition to poor heating or cooling output, refrigerant leaks can lead to ice buildup on coils, further impairing function. Since refrigerant handling requires certification, this repair must be done by a professional.

Electrical Component Failures in Heat Pump Repair

Faulty capacitors, relays, or wiring can stop the unit entirely. Electrical faults may present intermittently, making them tricky to diagnose without proper tools. Regular inspections can catch signs like burnt wiring insulation or corroded connectors before they cause a shutdown.

Most heat pump issues stem from neglected maintenance. A simple filter change or coil cleaning can prevent the majority of service calls.

Troubleshooting Tips for Heat Pump Repair in Homes and Businesses

Before calling an HVAC technician, there are several safe checks you can perform:

- Check Thermostat Settings, Ensure the system is in the correct mode (heat/cool) and set to the desired temperature.

- Inspect Filters, Replace dirty filters every 1, 3 months.

- Clear Outdoor Unit, Remove debris, snow, or plants within a two- to three-foot radius.

- Check Breakers and Power Supply, Reset tripped breakers if necessary.

- Listen for Unusual Sounds, Grinding or squealing noises may indicate mechanical issues.

Additionally, visually inspecting refrigerant lines for frost or moisture can provide clues about leaks or airflow problems. Monitoring your energy bills is another indirect troubleshooting method, sudden increases often indicate reduced efficiency. Keeping a log of any unusual behavior, such as short cycling or uneven heating, can help technicians diagnose the issue more quickly.

For more advanced guidance, see our detailed guide on heat pump repair advanced troubleshooting and preventive measures.

When to Call a Professional for Heat Pump Repair

If you suspect refrigerant leaks, electrical failures, compressor problems, or persistent freezing, contact a certified HVAC technician. Attempting these repairs yourself can be dangerous and may void warranties. Professionals have access to diagnostic tools, such as manifold gauges and thermal cameras, that can pinpoint problems in minutes. Timely intervention not only restores performance but also prevents damage to expensive components.

For ongoing maintenance advice, see our guide on Essential Maintenance Tips for Air Source Heat Pumps.

Case Study: Small Business Heat Pump Repair and Energy Savings Through Preventive Maintenance

A small retail store in Vermont installed a cold climate heat pump in 2023. Initially, they faced frequent icing on the outdoor unit during winter. After an inspection revealed clogged coils and an obstructed defrost cycle, they implemented a monthly cleaning schedule and upgraded to a smart thermostat for better control. Over the following year, heating costs dropped by 18% and repair calls reduced to zero.

Beyond cost savings, the store reported improved indoor comfort, with consistent temperatures that kept customers and staff happier. The smart thermostat provided remote monitoring, allowing the owner to adjust settings during off-hours, further optimizing energy use. By committing to preventive maintenance, the business avoided an estimated $1,500 in potential repair costs, demonstrating that small investments in upkeep can yield substantial returns.

| Action Taken | Result | Timeframe |

|---|---|---|

| Monthly coil cleaning | Eliminated icing issues | Immediate |

| Smart thermostat installation | Optimized heating cycles | Within 1 month |

| Professional inspection | Prevented compressor damage | Annual |

Industry Trends and Future Outlook for Heat Pump Repair

Modern heat pumps now integrate with smart controls and remote diagnostics, alerting owners to maintenance needs before a failure occurs. Cold climate models are designed for efficiency even in sub-zero conditions, reducing reliance on backup systems. Government incentives, such as the U.S. Inflation Reduction Act in 2025, offer tax credits covering up to 30% of installation costs, encouraging wider adoption.

Industry data shows that by 2030, global heat pump installations could triple, driven by decarbonization policies and rising energy costs. Manufacturers are focusing on improved refrigerants with lower global warming potential, and innovations like dual-source heat pumps that can draw energy from both air and ground. As technology evolves, predictive maintenance powered by AI will likely become standard, identifying issues before they impact performance.

For insight into upcoming innovations, check out The Future of Heat Pump Technology: Innovations to Watch in 2025 and related HVAC market trends for 2025.

Tools and Resources for Effective Heat Pump Repair Troubleshooting

- Smart Thermostats, Provide detailed performance analytics and remote control.

- Filter Change Reminders, Many systems now alert you when it’s time to replace filters.

- Professional Maintenance Plans, Regular inspections by qualified technicians can detect issues early.

- Energy Monitoring Devices, Track system consumption to spot inefficiencies.

Additional resources include mobile apps that integrate with HVAC systems, offering step-by-step troubleshooting guides and seasonal maintenance checklists. For commercial users, building management systems can automate diagnostics across multiple units, streamlining upkeep. Investing in quality tools not only aids in resolving current problems but also helps maintain optimal performance year-round.

These tools not only aid troubleshooting but also contribute to long-term energy savings.

Making Heat Pump Repair Reliability Work for You

Heat pumps are a critical component of sustainable heating and cooling strategies. By understanding common issues and taking proactive troubleshooting steps, homeowners and businesses can maintain peak efficiency, avoid costly repairs, and extend system life. Start with simple checks, like thermostat settings and filter changes, then invest in smart controls and regular professional maintenance. In doing so, you’ll not only save money but also contribute to a greener energy future.

Reliability also means peace of mind, knowing your system will perform when you need it most, whether during a winter cold snap or summer heatwave. By creating a maintenance routine and leveraging modern technology, you can keep your heat pump operating efficiently for 15 years or more. The combination of user awareness, timely service, and energy-smart upgrades transforms your heat pump from a basic appliance into a long-term investment in comfort and sustainability.

If you’re considering an upgrade or want to maximize your current system’s performance, explore our resources on Heat Pump Maintenance in 2025: Key Tips for Efficiency and take action today.

No Responses